Downloads

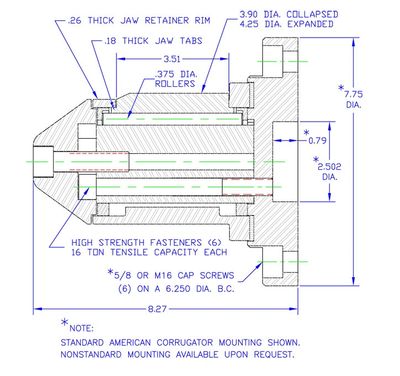

The patented Most Durable 410 Core Chuck is the highest capacity, most advanced roller action torque activated core chuck made to serve the corrugating industry. This new generation core chuck was designed to solve the increasingly common problems of less rugged torque chucks. After two years of prototype testing, production units with redesigned patented features began service in 2003 and are now performing flawlessly in several countries.

Advantages:

• Greater Expansion Range: 3.90 inch (99 mm)

to 4.25 inch (108 mm) (4 inch or 100 mm Core Capability)

• Longer Jaws to avoid core tear-out

• Heavy Duty Jaw Tabs

• High Speed E-stops without chuck damage

• Thicker Jaw Retainer Rim

• Greater structural load capacity for safety

• Fully Serviceable – No shrink fits or welds.

• 13200 lb max roll weight (6000 kg) 11000 inch-lb

max torque per chuck (1240 Nm)

• Made in the USA

• BEST WARRANTY AVAILABLE – 30 MONTHS

MD 410 Improvements

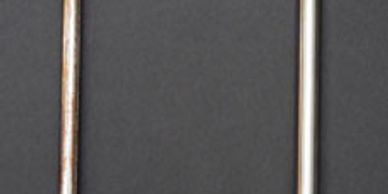

D 410 Rollers

D 410 Rollers are thicker and longer than old design rollers. Thicker rollers provide smoother action and prevent denting of mechanism parts.

Longer MD 410 Jaws

Longer MD 410 Jaws permit greater brake torque without core tear-out. MD 410 jaws also have 2.5 times thicker, much wider retention tabs to reliably avoid fracture. The thin, narrow jaw tabs of the old design chucks break off.

The MD 410 Jaw Retainer

The MD 410 Jaw Retainer Rim is 1.5 times as thick as the old design part to prevent failure by deformation or fracture.

Problems solved by the MD 410

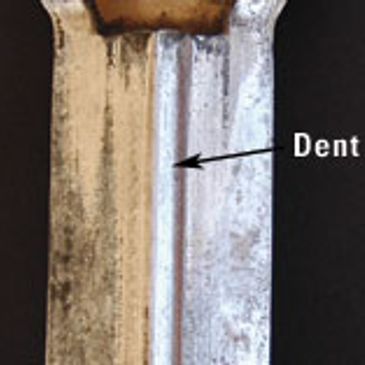

Roller Dents on Old Design Jaw

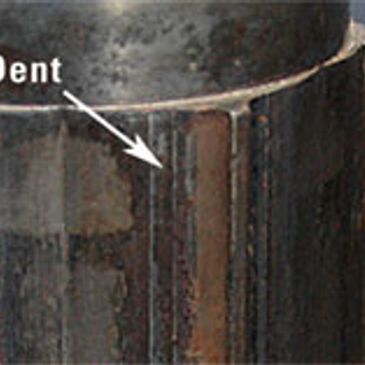

Roller Dent on Old Design Jaw Retainer Rib

Close the deal

Roller Dent on Old Design Hex

Dented Parts

Dents on the old generation chuck parts result from the high torque of web tension and/or e-stops, indicating poor mechanism load capacity. The force of the rollers against the jaws and hex dent those expensive parts. These dents then cripple the roller action, causing grip and/or release problems. Similarly, the dents in jaw retainer ribs indicate that the chuck fully expanded without achieving adequate grip, possibly resulting in core tear-out. The rollers do not even touch the ribs if the chuck grips correctly. The dented parts photographed were furnished by an American corrugator. The chucks were taken from service due primarily to frequent failure to release the core and were replaced plant-wide by MD 410 chucks.

Failure Modes

The principal failure mode causing the dents is ordinary metallic yielding during a few intense loading events. Similarly, the principal failure mode of jaw tab breaking is metallic brittle fracture. In both cases, time dependent failure modes of wear and/or fatigue may have contributed but a replacement chuck of inadequate capacity is likely to have problems as soon as critical events are repeated.

MD 410 Improvements

The Right Time for a New Chuck

The demands on industrial equipment can increase over time. The demands on core chucks increase with heavier rolls, faster unwind and more abrupt e-stops. It is thus not surprising that core chucks designed 20 years ago have serious problems in modern corrugators. The MD 410 was designed after hundreds of chuck performance and chuck repair problems were analyzed. The compact structure affords space for longer jaws to avoid core tear-out. Contact stress yielding, jaw tab fracture and other failures are reliably avoided by high load capacity of both the structure and the expansion mechanism. The dual core size MD 410 is the long term solution to costly problems.

MD 410 – Most Durable 4 inch/100 mm core chuck Patent Number: US 7,077,356 B2

Copyright © 2019 core-chuck.com - All Rights Reserved.